China Coated Glossy Surface PVC Marble Sheets For Wall manufacturers and suppliers | JIAXING

Wall Coating Glossy PVC One of the most significant advantages of marble sheets is their durability. This material is highly resistant to abrasion, making it an excellent choice for high-traffic areas. Unlike traditional marble, which scratches and stains easily, the coated glossy surface of PVC marble sheets provides a protective layer that extends their lifespan.

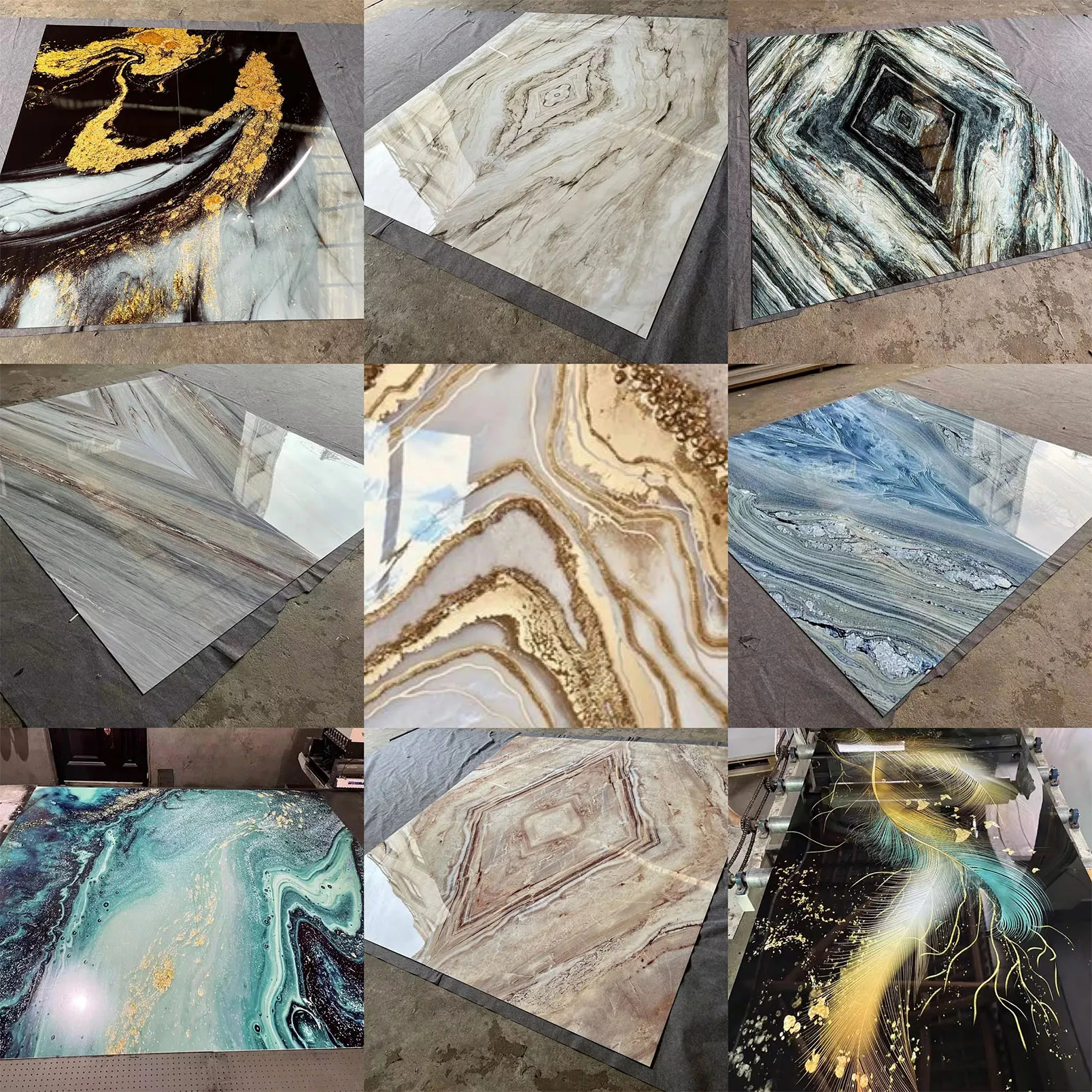

In addition to durability, wall coating glossy PVC marble sheets offer unparalleled aesthetic appeal. Its smooth and shiny surface gives it a luxurious look that instantly enhances the aesthetics of any space. Available in a variety of color options and realistic marble patterns, this material offers endless design possibilities, allowing you to achieve your desired wall look without compromise.

Product information

|

Common Thickness For Reference |

|||||

|

Product Name |

PVC UV marble sheet |

||||

|

Product Pattern |

Please refer tothe color card below or contact us |

||||

|

Product Size |

Regular size1220*24401220*2800,1220*3000 More sizes,please contact us |

||||

|

Product Thickness |

Regular thickness:2.5mm,2.8mm,3mm,3.5mm,4mmMore thickness,please contact us. |

||||

|

Product Material |

40% PVC+58% Calcium carbonate+2% 0thers |

||||

| Thickness(mm) | Tolerance (mm) | Weight(kg/pc) | Tolerance(kg) | MOQ(20GP/pcs) | |

| 1.3mm | ±0.05 | 8.0kg/pc | ±0.5 | 3000pcs | |

| 1.5mm | ±0.05 | 8.2kg/pc | ±0.5 | 2700pcs | |

| 2.0mm | ±0.05 | 12.3kg/pc | ±0.5 | 2000pcs | |

| 2.5mm | ±0.05 | 15.3kg/pc | ±0.5 | 1600pcs | |

| 2.8mm | ±0.05 | 17.2kg/pc | ±0.5 | 1400pcs | |

| 3.0mm | ±0.05 | 18.4kg/pc | ±0.5 | 1300pcs | |

| 3.2mm | ±0.05 | 19.6kg/pc | ±0.5 | 1250pcs | |

| 3.5mm | ±0.05 | 21.5kg/pc | ±0.5 | 1150pcs | |

| 4.0mm | ±0.05 | 24.5kg/pc | ±0.5 | 1000pcs | |

| 5.0mm | ±0.05 | 30.7kg/pc | ±0.5 | 800pcs | |

| 6.0mm | ±0.05 | 36.8kg/pc | ±0.5 | 650pcs | |

HIGH-QUALITY MATERIAL

|

High gloss plate |

Mirror effect, fashionable and beautiful |

|

Puguang plate |

Highly reflective, easy to wipe and wash |

PVC marble sheet Craftsmanship:

1. Heat transfer film: high-quality transfer film, high simulation, clear texture.

2. UV coating wear resistant: TOP A quality UV paint, bright color, prolong the service life of the panel.

3. PVC base board: High-density environmentally friendly base material, stable and compressive, and outstanding environmental performance.

4. PE protect film: Cover the surface with PE film to protect the surface from scratches

Feature of product

Another major advantage of wall coating glossy PVC marble sheets is their ease of maintenance. Unlike natural marble, which requires regular sealing and polishing to maintain its appearance, PVC marble sheets only require simple cleaning to keep them shiny and new. Its smooth surface is resistant to dirt and stains, making it a low-maintenance option for interior wall paneling.

Furthermore, installing wall coating gloss finish PVC marble sheets is a simple process that does not require specialized skills or equipment. The material is lightweight and easy to handle, making it a cost-effective choice for new construction and renovation projects. Its seamless installation helps minimize downtime and disruption, making it a practical choice for commercial spaces where time is of the essence.

In terms of environmental impact, wall coating glossy PVC marble sheets offer a sustainable alternative to natural marble. This material is manufactured using environmentally friendly processes and is recyclable, making it a responsible choice for environmentally conscious consumers. Additionally, its long service life and low maintenance requirements reduce the need for frequent replacement, further contributing to its sustainability.

In summary, wall-coated glossy PVC marble sheets are an excellent choice for interior wall paneling. Its combination of durability, beauty, ease of maintenance and sustainability make it a superior choice compared to traditional materials such as natural marble. Whether you are looking to enhance the visual appeal of your home or create a sophisticated ambience in a commercial space, this innovative material is sure to impress. With its many benefits, there’s no doubt that coated glossy PVC marble wall panels are becoming more and more popular with designers and homeowners alike.

Advantages

Crystal clear

Microcrystalline stone material, the surface is finely polished, crystal clear, and the texture style is beautiful and atmospheric.

Protection performance

Ceramic glaze coloring, recyclable, non moldy and damp, waterproof and flame retardant, good performance

Fire retardant

BI grade fire-proof,flame-retardant and self extinguishing when leaving the fire

We have more designs of PVC marble sheet, Customed.

Application

PVC marble sheet (UV board)application:

Uv board can be used in offices, Lobbies, Super Markets, Malls, Modern class rooms,Auditoriums, Libraries, Hospitals, Clinics,Multiplexes, Gaming Zones, Cinema Halls, Studios, Art Galleries, Exhibition centers,Marriage Places, Clubs, Gyms, Beauty Parlors, Salons, Fitness Studios, Yoga Centers, Book Stores , Home Decoration , Restrooms,washroom.

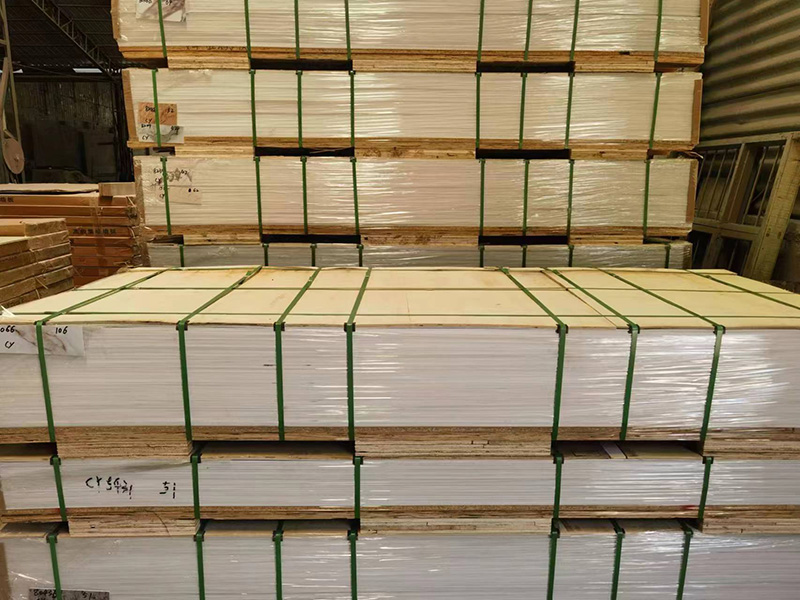

Packing

How to Install UV Marble Board ?

1. The bottom layer of the confimation and clean the bottom to be fully dry,so that the bottom level.Remove dirt and rubbish.The bottom layer,please use the gypsum board or the magnesium plate and the surface smooth and waterproof material plate.

2. Markingand Positioning In accordance with the size of the decoration,the shape of the bottom line,positioning.

3. Double side tapeadhesive bonding tape at the tixed position,hard pressed to make its cement. Usage:the wall is about 3.3/m2 of the ceiling is

about 4.3/m2.

4. Adhesive glue Cut the hose glue bottle mouth,leaving the cigarette weight(about 7mm) the width of the exit,and then squeeze the glue,(tape beside the position in the adhesive glue into a wire bound usage on the wall about 0.5 A/m2 the ceiling about 0.6A/m2.

5. Double sided adhesive tape for the removal of the adhesive tape Stripping,remove the Separation ofpaper.

6. In 10 minutes after the bonding of the decorative plate,the decoration plate is bonded to the fixed position.Theposition of the hands to press the tape,to make it fully bonded.Please note that you can not move or re-bond.

7. Maintenace of 1days during the course of the adhesive glue.